Web Menu

Product Search

Exit Menu

Why Work With A DIN Standard Cast Steel Valves Manufacturer Today?

DIN Standard Cast Steel Valves are a key component in industrial piping systems, valued for their durability, standardized dimensions, and consistent performance. They are used in chemical plants, petrochemical facilities, and power generation systems where reliability under pressure and temperature fluctuations is critical.

Working with a DIN Standard Cast Steel Valves Manufacturer ensures these valves are built to meet exact specifications and international standards, supporting long-term operation and reducing operational interruptions.

Understanding the Role of DIN Standard Cast Steel Valves

DIN valves are designed according to the Deutsches Institut für Normung (DIN) standards, which set clear rules for dimensions, materials, and performance requirements. The standards guarantee:

- Dimensional Compatibility: Valves fit seamlessly into international pipelines.

- Material Reliability: Carbon steel or alloy steel constructions handle medium to high temperatures.

- Pressure Rating Assurance: Common PN ratings, such as PN16, PN25, or PN40, help engineers select appropriate valves for their systems.

A trusted DIN Standard Cast Steel Valves Manufacturer ensures these characteristics are consistently delivered, minimizing engineering complications.

Design Features and Industrial Benefits

DIN Standard Cast Steel Valves offer design features that meet practical industrial needs:

- Robust Casting Structure: Provides resistance to mechanical stress and minor corrosion.

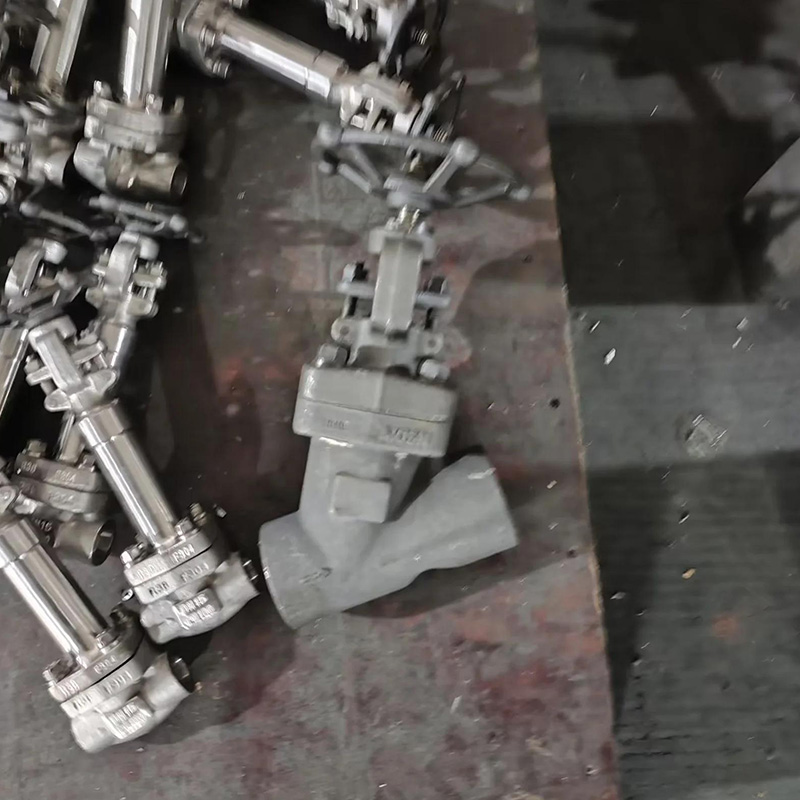

- Variety of Valve Types: Gate, globe, check, and ball valves allow engineers to select the right solution for flow control.

- Standardized Face-to-Face Dimensions: Simplifies installation and integration across different systems.

These features allow industries to maintain stable operations without frequent replacements or adjustments.

Pressure Performance and Testing

Pressure management is a key concern in industrial applications. DIN Standard Cast Steel Valves undergo rigorous testing to confirm their performance under operating conditions:

- Hydrostatic Testing: Verifies the valve body withstands specified pressures.

- Leak Testing: Reduces the risk of operational disruptions or emissions.

- Documentation and Traceability: Certificates and heat numbers track material origin and quality.

This ensures that each valve from a DIN Standard Cast Steel Valves Manufacturer meets design specifications before installation.

Material Considerations and Operational Longevity

Material selection plays a central role in valve performance:

- Carbon Steel: Suitable for standard industrial and petrochemical use.

- Alloy Steel: Ideal for higher temperature applications and resistance to chemical exposure.

Choosing the right material helps the valve endure pressure fluctuations, temperature changes, and medium-specific challenges, ensuring operational reliability over time.

Maintenance and Service Practices

Even high-quality DIN standard valves require routine attention to maintain consistent performance. Recommended practices include:

- Inspecting valve seats and seals to prevent leaks.

- Lubricating moving parts to reduce wear.

- Scheduling periodic pressure testing to confirm integrity.

Following these practices helps facilities reduce downtime and maintain smooth operations.

Partnering With a DIN Standard Cast Steel Valves Manufacturer

Selecting a reliable DIN Standard Cast Steel Valves Manufacturer provides multiple advantages:

- Technical support for selecting valves that fit unique system requirements.

- Expertise in producing valves to meet DIN standards for dimensions, pressure, and materials.

- Ability to handle bulk orders for large industrial projects with consistent quality.

- A manufacturer with proven experience ensures the valves perform as expected, supporting both safety and efficiency.

Applications Across Industries

DIN standard valves are widely used where operational reliability is critical:

- Chemical Processing Plants: Controlling corrosive and high-temperature fluids.

- Petrochemical Facilities: Handling volatile gases and liquids safely.

- Power Generation Stations: Regulating steam and cooling systems.

DIN Standard Cast Steel Valves combine durability, standardization, and performance for industrial operations. Collaborating with a qualified DIN Standard Cast Steel Valves Manufacturer guarantees valves meet international standards, perform reliably under pressure, and integrate smoothly into complex piping systems. Proper selection, testing, and maintenance ensure long-term operational stability in chemical, petrochemical, and power generation applications.

Recommended Products

The variety of models, to meet the development needs of various regions in the world.

-

Add: Zhongchuang lndustrial Zone, Bihu Town, Liandu District, Lishui, Zhejiang, P. R. China.

-

Tel: +86-578-2876658

-

Fax: +86-578-2876685

-

E-mail: rock@rockvalves.com

English

English русский

русский عربى

عربى Español

Español